Trenchless Trenching

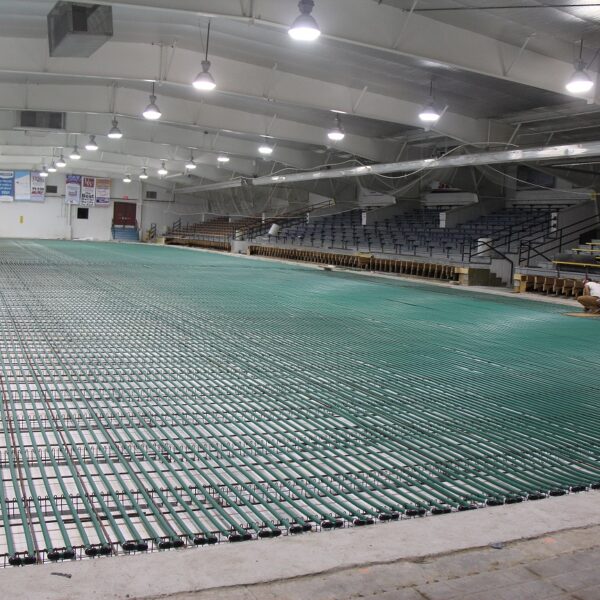

In 2008, Trenchless trenching was born. We were challenged with a geothermal field application that was originally proposed to be drilled using vertical wells at 540′ deep. Each well at this depth provides approximately 3 tons of cooling and heating BTU extraction and storage. The challenge is vertical boring does not work every time. Why? because the lay of the land may not allow you to retain the drill mud necessary to complete the bore field without destroying valuable property surrounding the proposed bore site due to slope. In this case it was a county club setting where we knew if we lost control of 100,000 gallons of drill mud we would be replacing a fairway which is not something any of us had planned on or budgeted for. So alternatives came into play and it was discovered that by applying horizontal boring in a unique pattern I could gain the surface area i need for BTU displacement. It was further discovered we could track our bores in a dish pattern to depths of 75′. This allowed us bore under the fairways, pop up in the rough and pull back our 540′ of loop pipe and gain the same benefit as if we were in a vertical bore.